On June 27, 2022, SaskPower announced they selected the GE Hitachi BWRX-300 Small Modular Reactor (SMR) for potential deployment in Saskatchewan. I thought this was quite exciting and set out to learn more!

Unfortunately the information available about the BWRX-300 online seemed to come in two formats: 2-page press release or 200-page regulatory document.

This post aims to hit the middle ground (so... 20 pages?) and answer the following questions, mostly in the context of a Saskatchewan SMR deployment:

- How does nuclear energy work?

- Boiling Water Reactors vs. Pressurized Water Reactors, etc.

- What is Saskatchewan's history exploring nuclear reactors and how did we get to present day?

- Why did SaskPower select the BWRX-300? What options were investigated?

- What is the business case to build an SMR - or multiple SMRs - in Saskatchewan?

- What is the timeline for SMR deployment in Saskatchewan?

- Where will Saskatchewan's first Small Modular Reactor be built?

- What would a BWRX-300 look like?

- Is the BWRX-300 safe?

- Who else is building the BWRX-300?

- Where does the fuel come from?

- Where does spent fuel, a.k.a. the "nuclear waste" go?

- How much waste will Saskatchewan SMRs create?

I've tried to cite my sources and provide lots of links. As always, let me know of any corrections or constructive criticism.

How does nuclear energy work?

An atom is made up of protons, electrons, and neutrons. Recall from chemistry that the atomic number represents the number of protons in the atom: 1 for hydrogen, 2 for helium, 6 for carbon, 8 for oxygen, 92 for uranium, etc. The nucleus of each atom is made of protons and neutrons, and is orbited by electrons. Electrons are largely the domain of chemistry; nuclear physics is all about nuclei.

Isotopes are types of atoms with the same atomic number (same number of protons) and a different number of neutrons. Here are some examples:

- Carbon-12 has 6 protons, 6 neutrons

- Carbon-13 has 6 protons, 7 neutrons

- Uranium-235 has 92 protons, 143 neutrons

- Uranium-238 has 92 protons, 146 neutrons

All isotopes of uranium are radioactive, which means the atomic nucleus is unstable and loses energy by radiation. Uranium-235 (a.k.a. U-235) is a fissile isotope, meaning it is capable of sustaining a nuclear chain reaction. Here's how Colin Tucker explains uranium fission:

If you can find a way to give a U-235 nucleus just a bit more energy, it'll probably give up and split into two smaller nuclei. [A] simple way to do this is to drop in another neutron - we could call this process "neutron capture" if we wanted to be technical about it. The neutron itself won't be carrying a lot of energy, but it will release energy when it joins with the nucleus - think of the noise you get when you snap a magnet onto a block of iron, and you'll get the idea.

That extra energy makes the U-235 nucleus pretty unstable. [The nucleus will split] into two smaller positively charged nuclei and will be pushed away from each other very strongly, accelerating to tremendous speed before bumping into other atoms and slowing down. Their speed energy will then have been converted into heat. [p9, How To Drive A Nuclear Reactor, Colin Tucker]

When U-235 fissions it releases two or three spare neutrons. When neutrons go on to cause other fissions, we get a chain reaction.

|

| Image source |

When neutrons are released after a fission event, they're travelling insanely fast. So fast that the odds of bumping into a nearby U-235 nucleus and sustaining a chain reaction are lowered. A "moderator" is used to slow down those neutrons and thereby improve the odds of bumping into a nearby U-235 nucleus, sustaining a nuclear reaction. Water (a.k.a. "light" water) is used as a moderator in many reactor designs, but Canadian CANDU reactors use heavy water. The flow of moderating water through the reactor also serves as a coolant.

Why is heavy water used on CANDUs? Over 99% of uranium isotopes in nature are U-238, which are not capable of sustaining a nuclear chain reaction on their own (they are not fissile). Just 0.7% of natural U isotopes are U-235 (which are fissile). For many nuclear reactor designs uranium has to be enriched to increase the proportion of U-235 in the fuel, typically to 3-5%, to sustain the chain reaction. Because the heavy water used by CANDU reactors is a more effective moderator than "light" (normal) water, it is able to sustain a nuclear reaction (slow down neutrons) without enriched fuel.

Boiling Water Reactor (BWR) vs. Pressurized Water Reactor (PWR) vs. CANDU (PHWR)

Once you start reading about types of nuclear reactors you find the acronyms BWR and PWR all over the place. This is intimidating to beginners but just remember: it's all about making steam.

In a Boiling Water Reactor, the nuclear reaction boils water into steam which is used to directly spin a turbine. The steam (which is radioactive) is condensed and recirculated back to the reactor in a closed-loop to be boiled again.

|

| Image Source by Robert Steffens |

Since the BWRX-300 is a BWR, if you're interested in learning the details of just how a BWR boils water with nuclear energy, I recommend this 20-minute YouTube video.

In a Pressured Water Reactor (PWR), the reactor heats water in a closed-loop primary circuit. The primary circuit, which is under high pressure to prevent boiling, flows through a heat exchanger which generates steam in a separate secondary circuit, which spins a turbine to generate electricity.

|

| Image source |

A CANDU reactor is a Pressurized Heavy Water Reactor, which is similar to a PWR in that a primary circuit of high-pressure (heavy) water is run through a heat exchanger to heat water in the secondary circuit, which spins the turbine. Because the reactor uses heavy water (a more effective moderator), natural uranium can be used as fuel (though my understanding is the fuel is typically slightly enriched).

|

| Image source |

What's Saskatchewan's history with nuclear reactors and how did we get to present day?

Maybe recent SMR news has you asking how we got this far. It turns out that SaskPower has been studying nuclear power since at least 1972, according to their historical reports page (see also: more recent reports). For a long time they have been doing their due diligence as a utility and evaluating potential options. Here's a partial timeline:

- 1972: B.H. Hamilton writes a high-level report, "Review of Nuclear Power Generation". It is a review of technology and economic assessments available at the time. It's more background reading about nuclear than anything specific to the province.

- 1975: A preliminary report titled "Considerations for Siting A Nuclear Powered Generating Station in Saskatchewan" is issued and takes a stab at identifying a location for a 1000 MW reactor.

- 1991: The Saskatchewan Electrical Energy Options Review Panel issues a 222-page report and position statement on numerous potential future power sources, including nuclear.

- Nuclear was described as "undoubtedly the most contentious option" but viable and "should be considered when planning Saskatchewan's electrical energy future".

- Public feedback (page 42) contrasted benefits like zero-emissions and highly-concentrated, manageable waste streams against long-term storage risks, public perceptions, and then-recent disasters like Chernobyl and Three Mile Island.

- It's interesting to compare how the report discusses the "potential utilization" of coal (on p75): "abundant low-cost... low-sulfur... clean coal [is] a considerable improvement on conventional coal... should be regarded as viable... possible support by the federal government for clean coal... looks attractive from many viewpoints"...

- ... with the "potential utilization" of nuclear energy (p101): "undoubtedly the most contentious... deeply felt concerns about nuclear safety... reactor accidents... the fear of possible adverse health effects... a viable option... must be viewed in a broader context than the simple generation of electrical energy and treated his way when making societal choices".

- 1994: A report titled Technical Assessment of the Nuclear Option for Saskatchewan found "a CANDU 3 will provide adequate protection for human health and environment... [and] an increment of additional protection belong that provided by the 22 CANDU plants currently operating in Eastern Canada." Cost objectives were "theoretically achievable" but allow "little or not margin for unforeseen events over a 40-year period of operation" - a tight squeeze, economically.

- 2006: Over a decade later, SaskPower presents "Power Generation - Exploring Saskatchewan's Nuclear Future" to the Sask. Association of Rural Municipalities (SARM) and the University of Regina. Then-economical nuclear plants had greater than 1000 MW capacity, which posed integration challenges for SaskPower's grid. "Build for export" was an option considered: a nuclear power plant operated in-province, with all power exported and totally isolated from the Saskatchewan grid.

- 2007: SaskPower has Stantec Consulting Ltd. examine Preliminary Siting of a Nuclear Power Plant, focusing on the Lake Diefenbaker and Lac La Loche regions.

- 2018: Natural Resources Canada kicks off the Canadian Small Modular Reactor Roadmap. This collaboration between provinces, utilities (including SaskPower), and NRC is an effort to get major players in Canada pulling in the same direction. Key recommendations include demonstrating SMR technology, sharing (financial) risks between government, utilities and industry, proactively enabling safe and secure legislation and regulations, and building knowledge capacity and engagement across Canada.

- 2020: Canada's SMR Action Plan transforms the roadmap to actions, widening the stakeholder groups to over 100 organizations ("the federal government, provinces and territories, Indigenous Peoples and communities, power utilities, industry, innovators, laboratories, academia, and civil society"). The Action Plan defines actions around SMRs to enable clean, safe, and affordable energy for Canadians. Local participants include: SaskPower, the Government of Saskatchewan, Saskatchewan Mining Association, Saskatchewan Research Council, and the Sylvia Fedoruk Canadian Centre for Nuclear Innovation.

- March 2021: Ontario Power Generation (OPG), Bruce Power, NB Power and SaskPower deliver the report, Feasibility of Small Modular Reactor Development and Deployment in Canada report. This document evaluates the feasibility of SMRs in Canada, considering economics, available technology, and federal, provincial, and industry support.

One key detail from this report is Saskatchewan is considering not one, but four SMRs. The site of the first SMR would be sized and licensed to accommodate the second. Details are not given about the third and fourth. - April 2021: Alberta joins the inter-provincial SMR MoU and is welcomed by Ontario, Saskatchewan, and New Brunswick.

- December 2021: OPG announces the selection of the GE-Hitachi BWRX-300 SMR as the preferred technology developer for Ontario's first SMR, to be constructed at the Darlington nuclear site by 2028. See also: Darlington New Nuclear site.

- March 2022: The Governments of Ontario, New Brunswick, Alberta, and Saskatchewan publish A Strategic Plan for the Deployment of Small Modular Reactors. The document identifies "key actions the provinces can take to enable a decision on whether to proceed with SMRs."

This document is probably the most current and comprehensive snapshot of the state of SMRs in Canada (as of this post). Worth a read if you're into the details! - June 27, 2022: SaskPower announces the GE-Hitachi BWRX-300 has been selected for "potential deployment" in Saskatchewan.

- July 27, 2022: SaskPower pushes the plant siting decision for location of the first two SMRs to 2024 (deliverable was originally planned for 2023).

Why did SaskPower select the BWRX-300? What options were investigated?

SaskPower considered 3 SMR designs:

The evaluation weighed factors like safety, technology readiness, generation size and type, and expected costs of electricity.

The inter-provincial Strategic Plan describes how Ontario Power Generation (OPG) and SaskPower have been working very closely together on the detailed assessment of the three SMR technologies listed above. So, it should be unsurprising that SaskPower selected the same SMR as OPG.

(Updates 2022-09-16) Check out a presentation from SaskPower to the Saskatchewan Association of Regional Municipalities from October 2021. There's a terrific speaker from SaskPower laying out the what, where, why, when, how to interested RMs in the province. The recording is nearly 2 hours but is worth watching if you're keen for great information straight from an informed expert.

What is the business case to build an SMR - or multiple SMRs - in Saskatchewan?

The March 2021 Feasibility Study is a great source of information.

SaskPower's long-term obligations include delivering electricity to customers at the lowest possible cost, and meeting all federal emissions regulations including the retirement of ~1400 MW of coal generation by 2030. SaskPower also has a self-set goal of increasing renewable power generation to 40% of their total generating capacity by 2030.

To achieve these objectives SaskPower "plans to add 1,118 MW of natural gas generation, 685 MW of wind generation, 190 MW of hydro imports from Manitoba and 183 MW of solar/other between 2021 and 2029."

SaskPower recognizes that building lots of new natural gas infrastructure in the 2020s will make further greenhouse gas emissions reductions difficult "until the 2040s". In other words, from an economic standpoint why would we need SMRs if we have a bunch of brand-new natural gas power plants? So the utility is evaluating SMRs now, along with other technologies like expanded solar/wind and expanded carbon capture and storage.

Key feasibility considerations and business case drivers for Small Modular Reactors include:

- Competitive price for power. This is "promising" in the report, and more detailed cost estimates will be delivered as Ontario proceeds with its first-of-a-kind BWRX-300 deployment at Darlington.

- Close collaboration with provinces and industry partners. Because Saskatchewan is new to nuclear power plants, they've partnered with and are closely following Ontario's deployment to reduce cost and schedule risks at home.

- Fleet-based deployment. If the provinces can create a pipeline of SMR projects that continue getting cheaper and more efficient to construct with each new plant, that improves overall economics.

- Federal government support. SaskPower and the other provincial utilities propose 50-50 cost sharing of SMR planning costs with the feds. Without a clear federal commitment to cost sharing SMR development, "deployment in Saskatchewan is unlikely to proceed."

- Deep greenhouse gas emissions. If the full SMR deployment plan is executed, it "could avoid the emission of as much as 73 Megatonnes of CO2 in Saskatchewan between 2025 and 2050 while supporting the economically sustainable decarbonization of Saskatchewan’s electrical grid"

This chart is wild! It's saying that without SMRs, Saskatchewan would be so gas-dependent that after 2030 we won't be able to make a dent in emissions until 2049 (when something magical seems to happen). For more background on SaskPower's current generation mix, see this post. - Substantially offset negative economic impacts of the coal phase-out. Deploying 300-1200 MW of SMR capacity would have a huge positive impacts to GDP, wages in the province, and tax revenue (the alternative being paying Alberta for gas and private producers to generate it).

- Job creation. The Feasibility Study estimates ~728 full time jobs per year if (when) all four SMR units are operational.

- Reduced dependence on natural gas. An SMR strategy in the early-to-mid 2030s would support a "phase-out of gas for base-load generation between 2030 and 2050" and reduce the risk of regret capital - that's money spent building gas plants just to turn them off after a few years. See also: my recent post on natural gas in SK, and the image above.

- Indigenous engagement.

- New markets for Saskatchewan uranium.

What is the timeline for SMR deployment in Saskatchewan?

The inter-provincial Strategic Plan captures the timeline nicely with a graphic on page 51:

The decision to build additional SMRs would happen in the mid-2030s with construction following.

Where will Saskatchewan's first Small Modular Reactor be built?

The answer is: we don't know yet. I am under the impression that targeted community engagement has started (or will be started soon), and the decision will be made in 2024.

We have a couple clues from old reports.

The 1975 siting study comes up with the below "Top 3" potential locations. However, this report used a 1000 MW plant as a baseline, which would have different cooling water requirements than the two-SMR site being evaluated today.

The 2007 siting study focused exclusively on Lake Diefenbaker and Lac La Loche, with Diefenbaker performing better in every category. Three potential sites were identified (image below).

Lake Diefenbaker sites consistently scored higher than Lac La Loche sites, with disadvantages of La Loche including lack of accommodations and regional amenities for employees, and large capital costs related to the distance (transportation requirements and transmission infrastructure). The report recommended more study of the Diefenbaker sites to assess water security issues due to competing uses and climate change impacts.

A major caveat about the above historical studies. It's unclear (to me) at this point how much continuous cooling water the BWRX-300 (or two of them on the same site) will require to operate.

This GE fact sheet says "the BWRX-300 [can] passively cool itself for seven days without power or operator action during abnormal events, including station blackout." However, ongoing operation would probably require a continuous flow of cooling water. I can't figure out how much.

If the BWRX-300 has lower water requirements, another interesting idea: would the province build SMRs near Estevan to facilitate job transitions, where the province's 3 remaining coal power plants will be shut down by 2030?

|

| Image source |

(Updates 2022-09-16) In this October 2021 SARM presentation from SaskPower, the one firm siting clue SaskPower shared the SMR - if built - will be located in a Regional Municipality, which basically excludes cities. So: no SMR within Saskatoon city limits 😢 There were also some great clues about potentially locating the first two SMRs at a decommissioned coal site to take advantage of nearby water for cooling, and all the electrical and distribution infrastructure.

(Updates 2022-09-20) SaskPower has just announced two areas of study, one by Estevan and the other by Elbow. PDF links to study areas: Estevan, Elbow.

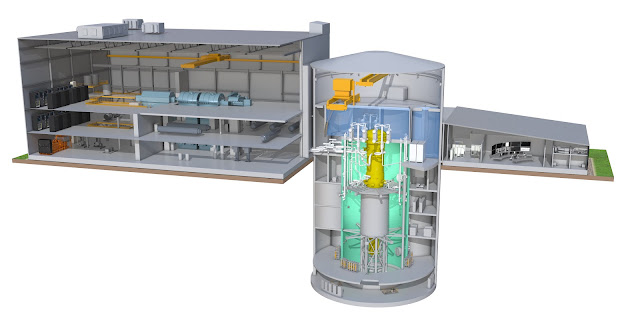

What would a BWRX-300 look like?

Here's a render of a plant site from GE's website:

Here's a cutaway from the reactor building:

In the above image, the yellow is the Reactor Pressure Vessel (RPV), the teal is the Primary Containment Vessel (PCV), and the blue is the Isolation Condenser Pool (ICS). These bits are discussed more below.

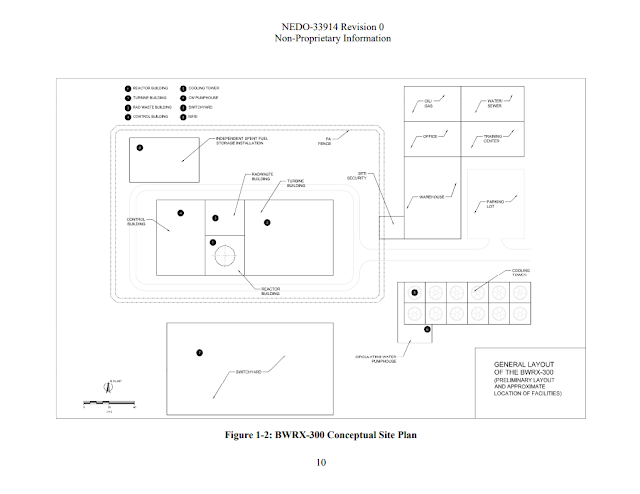

The YouTube video embedded on the GE page says the reactor building (shown in the image above) is about the size of a football field:

The site where the reactor will be located would be an of magnitude larger (image source: "Advanced Civil Construction and Design Approach Licensing Topical Report" retrieved from this US NRC page). Using a very scientific tool (Microsoft Paint) to measure pixels, the entire area in the rectangle below is about 13x the size of the reactor building footprint (which we know is a football field). I calculated the whole site is approximately 7 hectares. For two reactor units, more space would be needed.

Is the BWRX-300 safe?

Disclaimer: to discuss safety I need stress I'm not a nuclear engineer, nuclear safety engineer, or anything like that. My engineering field of practice (process control and automation) helps me parse some of the documentation, but I'll emphasize I approach this topic from an enthusiast, reader, listener, and learner perspective, not as a subject matter expert (SME).

Before looking at the BWRX-300 one might ask, is nuclear energy safe? The answer is yes. If you need convincing, check out Nuclear Safety from Our World In Data. Every form of energy generation (including nuclear) has risks, but all risks need to be put in perspective and mitigated with proper controls.

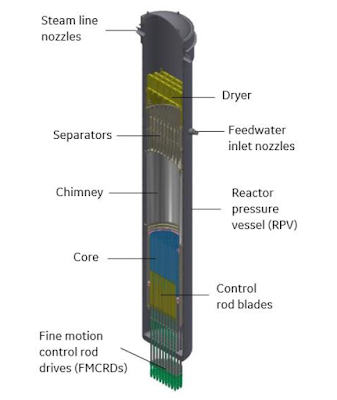

Let's look at a schematic of the BWRX-300 Reactor Pressure Vessel (RPV). This is where all the action happens. I'll again recommend this 20-minute YouTube video for details of how a BWR boils water.

A nuclear reactor core is hot in both the temperature and radioactivity sense; energy from the nuclear chain reaction heats water to make steam. Safety is all about keeping the core cooled, controlled, and contained in the RPV.

Consider the following partial, cherry-picked list of safety features of the BWRX-300 I found interesting.

- The BWRX-300 design is a "10th generation" Boiling Water Reactor design by GE Hitachi. It's an SMR evolution of a design called ESBWR, using many components from an existing, operational, tested, and licensed plant design called the ABWR. In other words: the BWRX is an evolution using many off-the-shelf parts, not a brand-new, untested design.

- The Reactor Protection System (RPS) is a collection of instruments, logic, automatic and/or manual controls, and "scram logic circuitry" that automatically inserts control rods into the core when unsafe conditions are detected. Control rods are made of materials that soak up neutrons. When neutrons are captured by the control rods they can't smash into other U-235 atoms, hence the nuclear chain reaction cannot be sustained. Control rods can be inserted electrically (when there is power to run motors) or hydraulically (when there is no power).

- The entire reactor pressure vessel is mostly buried below grade (underground).

Image source: ML21020A137.pdf from NRC

Enclosing the entire RPV is the Primary Containment Vessel (PCV). It's a gigantic metal tank that's leak-tight and is designed to contain radioactive fission products in the unlikely event of a Loss of Coolant Accident (LOCA). Like nesting dolls, the PCV is fully enclosed by concrete. - Design simplification. Layers of redundant systems add complexity (and risk, and cost) so where possible, GE Hitachi designers use passive, "natural phenomena-driven" safety systems.

An example is the Isolation Condenser System (ICS).

Let's say an upset causes the BWRX to "trip". A tree falls on a transmission line, so the BWRX has to shut down right away. The steam feed to the turbine generator is closed and the turbine is stopped. Control rods are inserted into the core, causing the chain reaction to stop - but the RPV is still insanely hot, boiling water and creating steam! And it will be hot for a while due to decay heat in the fuel.

If steam can't flow to the turbine generator, where does it go? It can't be allowed to build up in the RPV, as that would create a dangerous situation.

During a shutdown the operator (or the system automatically) opens a valve to the Isolation Condenser System. This is literally just a huge water heatsink located directly above the RPV. Both the images above and below illustrate this pool.

The hot steam flows through one of four sets of condensers. These are heat exchangers sitting in the Isolation Condenser (IC) Pool. The steam dumps its heat into pool while condensing back into water, where it flows back into the RPV to be boiled again, flow back through the ICS, dump more heat, etc. The cool (and safe) thing about this system is it doesn't require any pumps, power, or moving parts to work. It "just happens" due to natural circulation. Steam rises, condenses, cools, falls, boils.

This gigantic heatsink can safely control and absorb latent reactor heat for up to seven (7) days with zero operator intervention in a total blackout scenario.What happens after 7 days? Hopefully you have power back to run all the other electrical cooling and support systems, but if not: just replace the (now hot) water in the IC Pool with cold water to continue removing decay heat for as long as required.

This safety section was informed by this BWRX-300 booklet from the International Atomic Energy Agency's Advanced Reactors Information System database. It was also informed by episodes 182, 327, and 362 of the Titans of Nuclear podcast. Most images came from documents posted to the US Nuclear Regulatory Commission's page for the BWRX-300.

Who else is building the BWRX-300?

In addition to Ontario and Saskatchewan, Poland is looking to build at least 10 BWRX-300 units, with the first being operational as early as 2029. This bodes well for Saskatchewan; there should be at least a couple units in service by the time construction could start in 2030.

Where does the fuel come from?

The BWRX-300 uses a GE fuel bundles called GNF2. The advantage is this fuel is already designed, licensed, and proven; it does not have to go through a multi-year approval process of its own. The disadvantage (for the Canadian supply chain) is it is not manufactured in Canada, unlike fuel for the existing CANDU reactor fleet.

However, Cameco announced in July that they've signed an MoU with GE Hitachi and Global Nuclear Fuel (the subsidiary that makes GNF2) to see if they can get in on some of that action.

Where does spent fuel, a.k.a. the "nuclear waste" go?

One great thing about nuclear energy is it has the best-managed waste stream on the planet. Unlike every other source of electricity generation, nuclear waste is internalized (captured) when and where power is generated. Radioactive waste is much more tightly controlled and regulated than other types of hazardous substances. We know where it all is. We can't say the same for the carbon released into the air by coal and gas, or the waste streams from decommissioned wind turbines and photovoltaic solar.

Spent nuclear fuel is easy to handle safely. One might imagine leaky drums of glowing green ooze as seen on The Simpsons. In reality spent fuel looks exactly the same as new fuel: zirconium tubes full of hard, ceramic pellets.

When a BWRX-300 reactor is refueled, spent fuel will be stored in a spent fuel pool in the reactor building. The pool will be sized to hold 8 years' worth of spent fuel. After cooling in the pool for some years, it will be transferred to reinforced dry casks. Dry casks will (likely) be stored on site for some years, before being transferred to a Deep Geologic Repository (DGR).

The inter-provincial Strategic Plan has a good section about Canadian nuclear waste management, starting on p21.

Under the Government of Canada's Radioactive Waste Policy Framework, nuclear waste producers and owners are responsible for funding, organizing, and safely managing radioactive nuclear wastes. Waste management costs will be built into the cost of any SMRs built in Saskatchewan.

All used fuel from Canadian nuclear producers is currently safely held on sites in spent fuel casks. The Nuclear Waste Management Organization (NWMO) has responsibility for that spent fuel in the long term and forecasts the DGR to be operational in the early 2040s.

The NWMO are currently seeking a host community for a DGR. Here's a citizen's group page in South Bruce about the project. Even if the DGR is not complete on schedule, it's not impossible to imagine safely storing spent fuel on surface for decades to come.

There's a great chapter all about waste in the free e-book download, Why Nuclear Power Has Been A Flop. Chapter 2 busts the myth of spent nuclear fuel being "the most dangerous substance known to man [sic]", and lays out a compelling argument for spent fuel being a "beautifully small problem": the impacts are many orders of magnitude smaller than coal and gas (see below).

(Updates 2022-09-16) @FrantaJaro on Twitter pointed out an interesting detail (see thread), that BWRX-300 spent fuel will not fit inside the standard Used Fuel Container (UFC), which is designed for CANDU spent fuel's long-term storage in NWMO's DGR. According to the "Confidence in Safety - Revell Site" report from March 2022:

... the NWMO will assess the potential of using the current container design for these other fuels [BWRX-300 and other new reactors in Canada]. Fuel characteristics, geometry, and other considerations may require alternative or modified container designs to be developed. NWMO will leverage and build on the reference CANDU fuel container, as well as, international container designs developed for these fuel types. (p33)

How much waste will Saskatchewan SMRs create? Can we put it in perspective?

Let's grab some numbers from the BWRX-300 Status Report on the IAEA website and do some back-of-napkin math.

- Number of SMRs: 4 (let's assume Saskatchewan manages to build all four)

- Plant design life: 60 years

- Refuelling: Every 12-24 months (let's use 18 months in our estimates)

- Number of fuel assemblies per SMR: 240

- Weight of one fuel assembly: 324 kg

- Plant Capacity Factor: 95% (percent of time running per year)

- Plant Output: 300 MW

Total fuel used over the life of one SMR: 3,110,400 kg or 3,110 tonnes (1 tonne = 1000 kg).

If Saskatchewan built 4 SMRs as discussed above, that would generate 12,440 tonnes of spent fuel over 60 years. Let's round up to 20,000 tonnes, accounting for the mass of the reactor pressure vessels, turbines, and irradiated concrete and other plant components.

That's a big number! If that 20k tonnes were pure uranium (excluding cladding and other materials), it would fit in a cube 10 meters (33 feet) on each side.

From other perspectives, 20,000 tonnes of waste over 60 years is miniscule. The City of Saskatoon accepted 93,900 tonnes of garbage at its landfill in 2020 (source). So Saskatoon citizens generate the same tonnage of waste in one year as twenty BWRX-300's would generate in 60 years.

Let's compare the waste streams of four 300 MW SMR units with other sources of electricity used in Saskatchewan. Over a 60-year lifespan, four 300 MW SMRs running at 95% capacity factor would generate approximately 600 TWh of electricity.

Using this information we can calculate how much coal and/or natural gas it would take to generate 600 TWh of electricity. And with using this info we can calculate CO2 emissions. I've converted all the units to metric:

- Coal: 600 TWh x 1.12 pounds/kWh = 305,000,000 tonnes of coal.

A cube of coal with this mass would have edges that are 662 meters long.

~607,000,000 tonnes of CO2 emitted (why does the CO2 weigh more than the coal? see here) - Natural Gas: 600 TWh x 7.40 cubic feet/kWh = 126,000,000,000 cubic metres of gas.

A cube of gas this size would have edges that are 5 kilometers long.

~248,000,000 tonnes of CO2 emitted

A good question for people in Saskatchewan to reflect on would be:

What is our preference to generate 600 TWh of energy over the next 60 years?

Manage 20,000 tonnes of spent nuclear fuel?

Burn 305,000,000 tonnes of coal?

Burn 126,000,000,000 cubic metres of gas?

Our World in Data has a great analysis of land use by energy sources, illustrating how much land (including mining and minerals) each energy source requires on a per-MWh basis.

It doesn't matter of my back-of-napkin math is off by a little bit or even a whole order of magnitude. The point is that nuclear energy is so energy-dense that it eclipses coal and gas by multiple orders of magnitude in minimizing waste and harmful byproducts per unit of energy delivered. It eclipses every other source of electricity for minimizing land use per unit of energy delivered.

(Updates 2022-09-16). Here's a great waste visualization from the October 2021 SAMR-SaskPower presentation. SaskPower provided this response to a question about how much waste an SMR would create:

In a follow-up comment, it was clarified this specifically referred to high-level waste, not the medium- and low-level stuff like coveralls, papers, and gloves. I was stoked to find this because it confirms my back-of-napkin math is the right order of magnitude!That's it!

I hope that you have learned something new reading this post! As always, let me know of any corrections or constructive feedback.

Updates

2022-09-16: Added some details from a SK Association of Regional Municipalities (SARM) presentation by SaskPower (link), and an interesting detail about NWMO needing new storage containers for BWRX-300 fuel (Twitter thread). New paragraphs are clearly marked, previous content is the same.

2022-09-20: It looks like the SARM presentation has been taken offline :( Also updated the location section about the Estevan and Elbow areas of study.

Nice write up. Looking at it from a process engineer (but not in the nuclear industry) perspective.

ReplyDeleteCooling water required is proportional to the capacity relative to a 1GW plant, but will also be similar to a coal plant of similar capacity. This matters more for once through cooling (like at the Ontario CANDUs). For a bit higher cost evaporative cooling could be used, which will reduce water use by >90%, but evaporate (remove from the watershed) most of it. In theory drynairncooling could be used, but at considerably higher cost and a loss of net power output.

Net from all that is coalnsites are ideal if they are in the 300-600MW capacity range now, they will have access to the appropriate cooling and have transmission corridors already built. Along with general nose infrastructure (roads, parking, offices, mtce sheds / shops, etc).

On the waste, my understanding is for the BWRs it is typical to change 1/3 of the fuel each time, so waste is already much lower than you state. And if the MOLTEX project in NB goes well there will be reprocessing options to further reduce it.

Excellent summary Thanks for putting this together.

ReplyDeleteThank you for your kind comment! :)

DeleteExcellent post, Brahm. You’ve captured a huge amount of information and condensed it very well with your explanations, illustrations and links. Very easy to follow and understand. Thank you!

ReplyDeleteThank-you Erik! :)

Delete